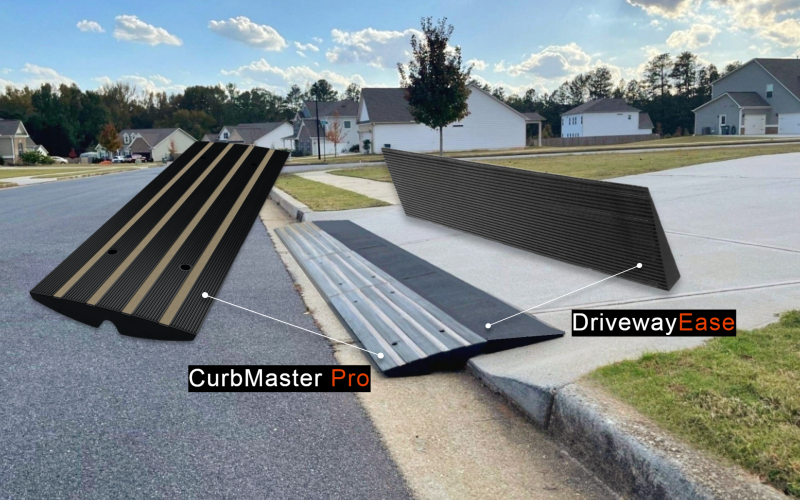

How To Install A Drainage Channel Under Your Curb Ramp

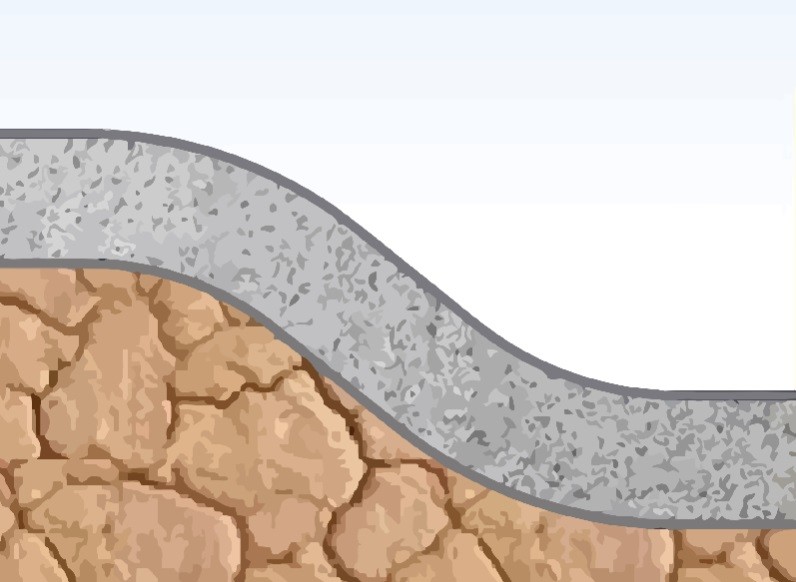

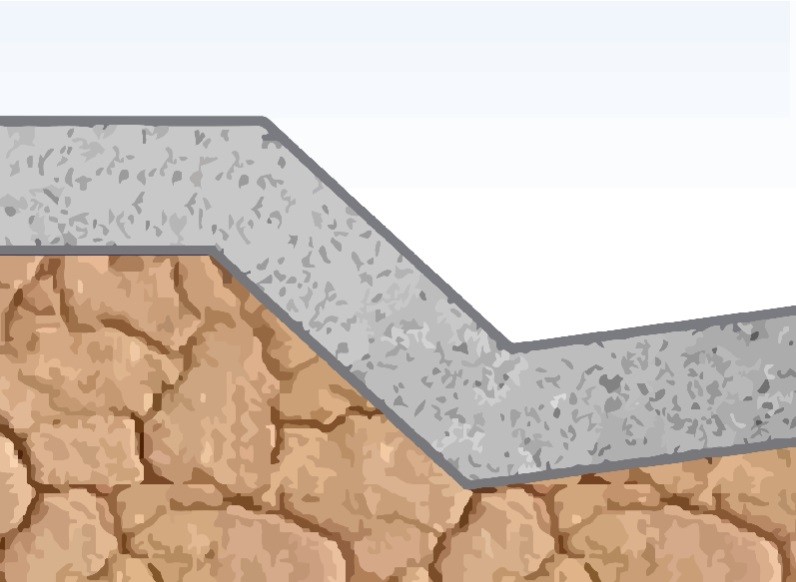

Water coming off a steep driveway will run right over the ramp just fine without obstruction. If you’re concerned about blocking water flow at the ends, we recommend feathering or tapering the edges smooth to meet the curb gutter. In other words, don’t create a hard right angle at the ends. This will allow water to flow freely around the ramp and back into the curb channel without causing blockage or ponding.

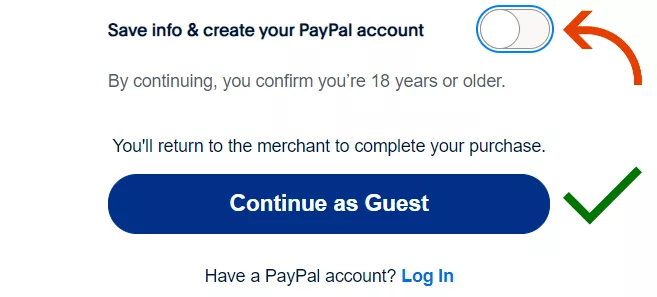

If you plan on installing a drainage channel underneath your ramp, this article will help guide you through our recommended process. First, decide whether you want to make your ramp removable. For this you would need a substrate, like a shower pan liner for example.

What You’ll Need:

(optional; removable)

(optional)

Construction Glue

(to anchor channel)

Trowel

(to mix & spread)

(filler compound)

Installing a Drainage Channel

Lay Substrate (Optional)

If you are using a substrate, lay it over the curb surface and tape it down to hold it in place. If you are not using a substrate, you can skip this step.

If you are using a channel strut, before you lay it down, apply a layer of duct tape over the slots at the top so the mixed compound doesn’t fall through when you spread it over the the top while building your ramp.

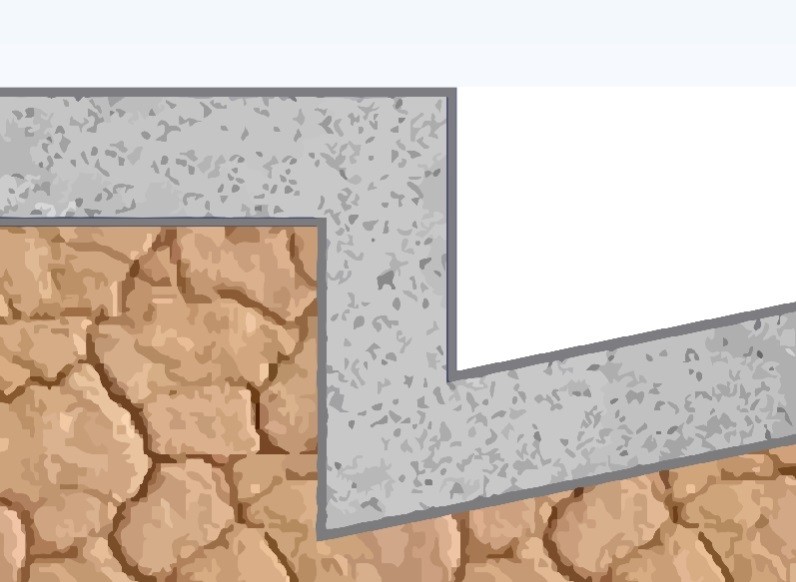

Lay Drainage Channel

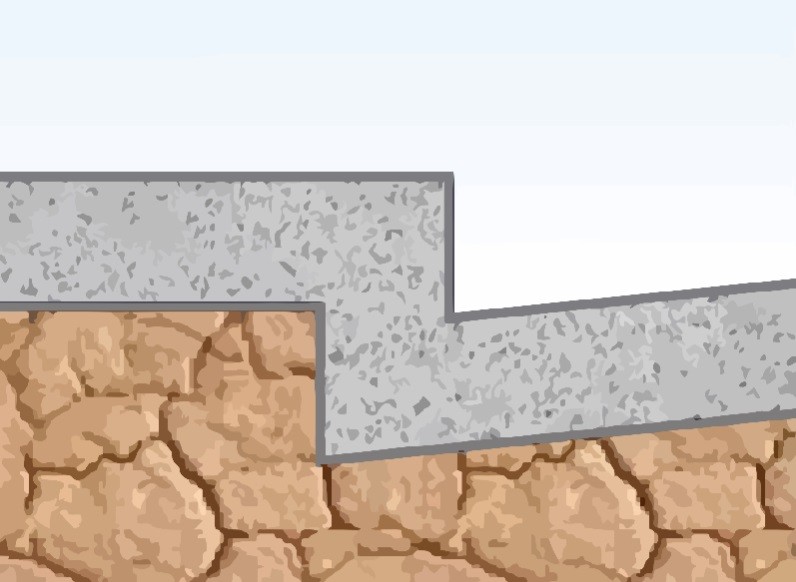

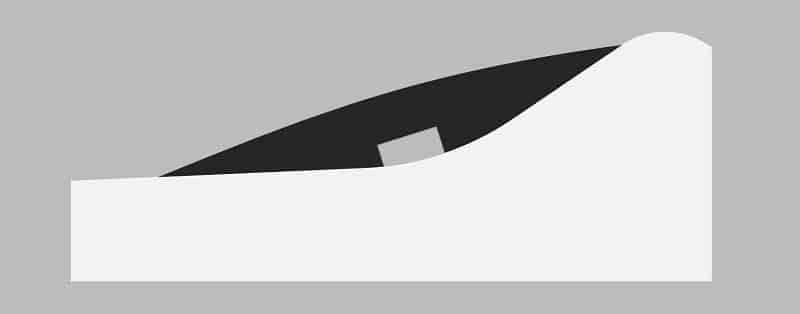

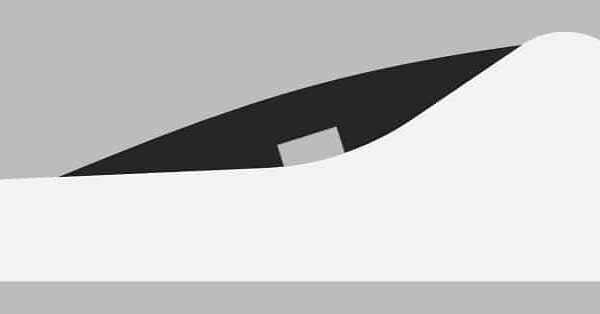

Next, lay the drainage channel in the middle of the curb gap, where water flows naturally. Use construction adhesive to anchor the channel to the substrate. Let it dry thoroughly. Warning: Do not use too big of a channel or pipe for your curb gap because it can compromise the integrity of the ramp. Make sure there is at least two inches of material above the channel for ramp surface stability.

While we do not endorse one specific product or brand, customers have reported success with items that can be found inexpensively at most local hardware stores including ¾ PVC Pipe, Channel Struts or Plain Steel Angles. Some local hardware stores even offer metal cutting on select products. Services and fees vary by store. Please see your local store for details.

Mix Composite & Adhesive

Mix the Curb Ramp composite with about ¾ of the enclosed adhesive using a trowel or drill mixer. The granules should be fully coated, but the mix should not be too “soupy”. Do not use the entire gallon for mixing, as a pint or so is recommended for priming. The shipping package or a 5 gallon bucket can be used for mixing. Use caution and put newspaper or other disposable material beneath the box to protect against accidental spillage.

Prime Curb Surface

Next, prime the substrate or curb surface as well as the top and sides of the drainage channel with a thin layer of the remaining adhesive.

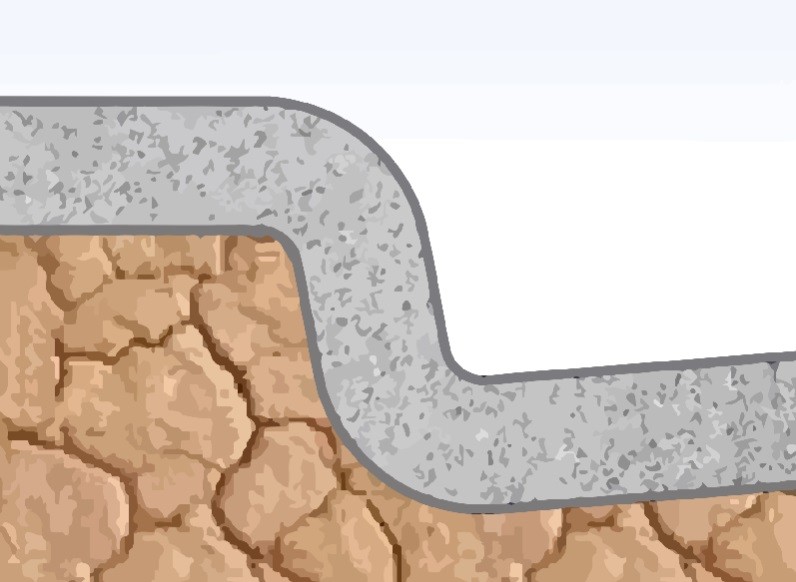

Spread Mixed Compound

Spread the mixed compound from the top of the curb to the street to fill the gap. Shape at the desired angle to best fit your curb to achieve optimal vehicle clearance; a 25° angle can be used as a good starting point. Compact and compress the material thoroughly using a trowel – especially around the edges and drainage channel to avoid gaps.