Video: 2 kits installed

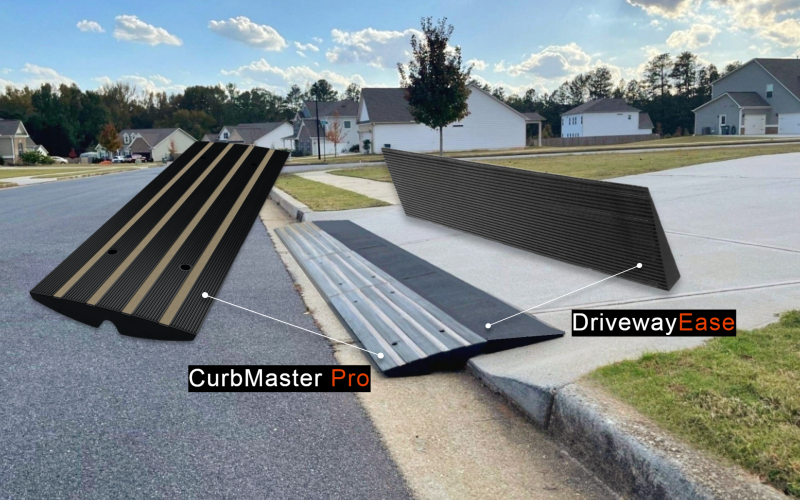

Steep Driveway Solutions 101

Step by Step - DIY Curb Ramp

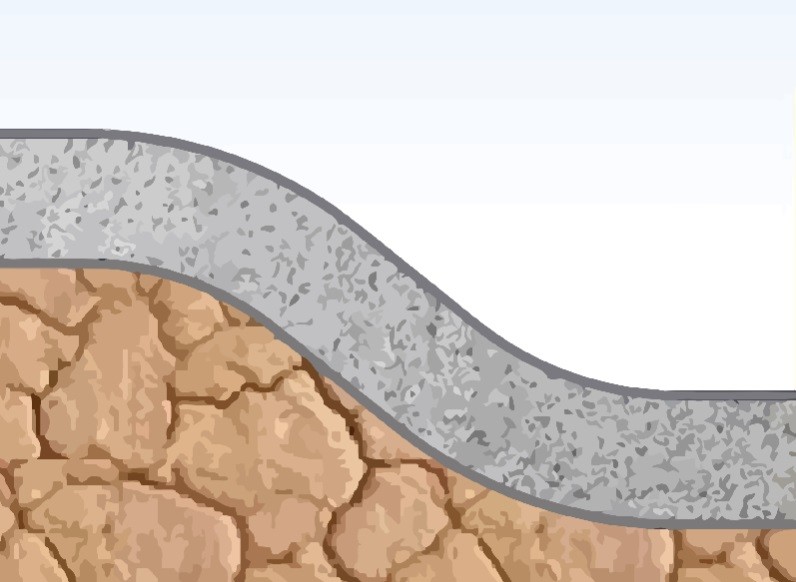

Clean/Lay Substrate

To begin installation of your driveway ramp, sweep and blow the curb gutter to remove all dirt and help the primer adhere to the curb surface. If your driveway curb is very badly soiled, you may want to pressure wash it and let it dry first.

If you are installing a removable ramp, lay substrate over the curb gap and tape it down, as you will be priming the surface of the substrate

, rather than the curb itself. Learn more

Mix

Mix the material with the adhesive using a trowel or drill mixer

until the granules are fully coated. You can use the shipping box or an empty 5 gallon bucket for mixing. Begin by pouring in approximately ¾ of the adhesive onto the granules and mixing completely until there are no dry patches and the granules are wet and fully coated. You can add more if needed but do not use the entire gallon all at once.There should be a little bit of adhesive left over which can be used for priming. Avoid leaving any dry patches that could potentially compromise the ramp’s integrity. The granules should be fully coated but the mix should not be too “soupy”.

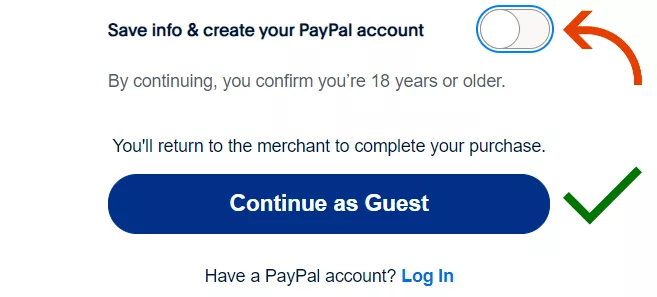

Prime

Prime the curb surface or substrate with any leftover adhesive using a paint brush

or roller to ensure a good bond.

Spread

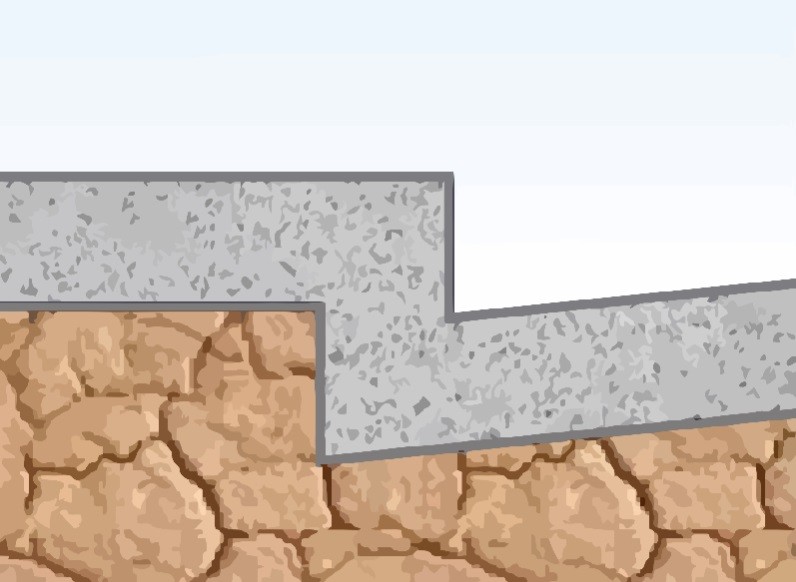

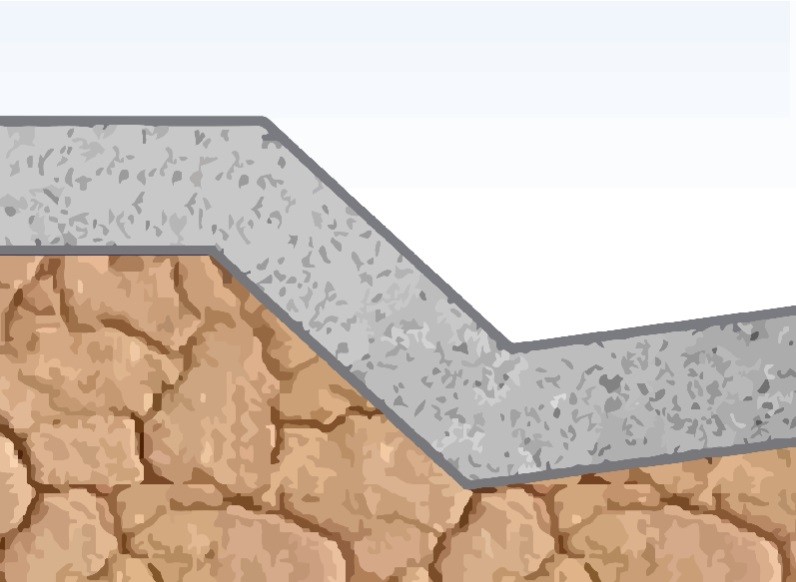

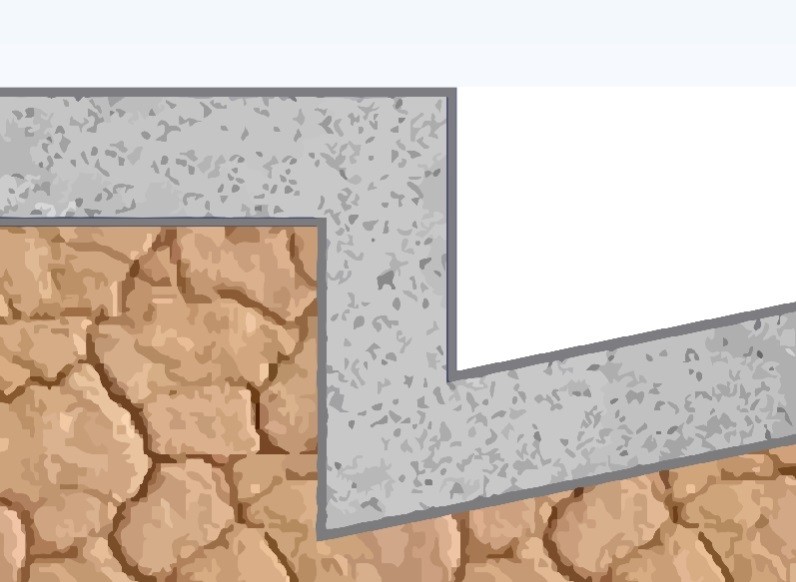

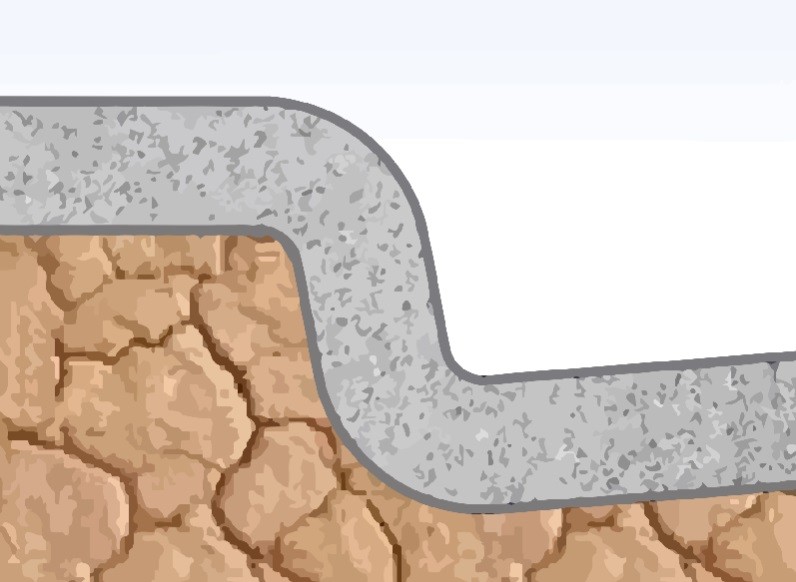

Spread the mixture to fill the dried curb curb surface at the desired angle to bridge the gap between the driveway and street. Slope and feather out the ends to facilitate water drainage. Do not create a hard right angle at the ends. Shape and compress the material using a trowel and form the edges for clean install lines. Tamp it down thoroughly to ensure there are no air gaps. Allow 24-48 hours to dry.

How To Make Your Curb Ramp Removable (Optional)

A standard Curb Ramp installation creates a powerful bond between the ramp, your driveway, and the street, making it a much more permanent solution than other pre-made driveway ramps. While conveniently mobile, pre-made driveway ramps rarely fit an individual’s specific curb well. But sometimes you want a removable ramp but don’t want to compromise with an expensive, ill-fitting pre-made ramp. To make your driveway ramp removable, you’ll need to lay a protective substrate over your curb before installing this material.

How To Install A Drainage Channel (Optional)

Installing a drainage pipe can help water flow naturally underneath the ramp. The process is straightforward and involves anchoring a channel or pipe in the middle of the curb gap using construction adhesive. These come in varies types, shapes, and sizes. The height of the tube should be proportional to your curb.

Information contained in this specification conforms to standard detail and product recommendations for the installation of the Curb Ramp as of the date of publication of this document and is presented in good faith. Curb Ramp LLC assumes no liability, expressed or implied, as to the architecture, engineering or workmanship of any project. For technical and safety information on the Curb Ramp Adhesive, please refer to the product’s description here.